|

Suspension

One of the

most distinguishing features of the Churchill tank was the suspension

system. 44 small diameter wheels arranged on 22 separately sprung

bogies, 11 to each track. The overall appearance was quite unlike

any other British W.W.II tank and whilst at first glance all bogies

look appear identical there were a surprisingly number of subtle

differences between some of them.

Description

Each suspension

unit consisted of a bracket, frame, axle, wheels and springs.

On the earlier Mks all units were independent being separately

bolted to the pannier floor above. Each unit was bolted to the

next by a tie plate attached to the outer faces and secured with

lock nuts. The rear bolt on each plate was allowed a small end

clearance but the front bolt clamped the tie plate firmly. With

the introduction of the MkVII the suspension was strenghtened

by replacing the tie plate between units 2 and 3 was with a welded

plate producing a combined suspension unit.

This change

was also retrospectively applied to some earlier Mks, especially

those in service as AVREs, Bridglayers and ARVs which were required

to carry heavier loads. Whilst many such 'upgrade' modifications

occurred post war, it is interesting to note the AVRE at Greye

Sur Mer which was recovered from the beach in its original condition

also has the combined 2 & 3 bogie unit.

The bogie

support bracket was constructed from welded plates and incorporated

large boss on each side to which the fulcrum shaft was clamped.

A bogie frame, mounted on bronze bushes, pivots about the fulcrum

shaft which was hollow and acted as an oil reservoir, oil nipples

at each end. One end of the bogie frame carried the axle and the

other end formed the lug for the rebound stop. On the upper side

of the axle shaft boss was a hard steel knife edge against which

the lower spring seat pressed. Each bogie unit contained four

springs with the exception of number 11 which is unsprung. The

outer two springs carried the load, the next inner spring, the

"bumper" spring, controlled the last 3/4 inches of bump

through and the inner most spring was there simply to retain the

"bumper" spring in position. The knife edge itself was

used to minimise any buckling of the springs by giving them freedom

to assume their own axial alignment. Due to the working radius

of the wheel, some slight buckling of the springs was unavoidable

and so the springs were arranged to be straight in line when they

were at the point of maximum stress i.e. maximum bump.

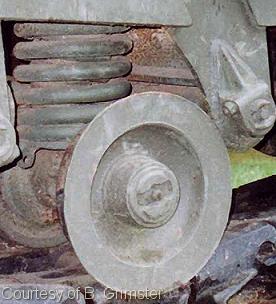

The wheels

themselves were 10" diameter and (perhaps surprisingly) were

simply push fitted on to the axle which rotated in white metal

bearings.

As with the

fulcrum shaft, the axle was hollow and acted as an oil reservoir,

being replenished via recessed nipples at the end of the axle.

There was another nipple at the centre of the bogie frame which

provided pressure relief.

Deflection

& Rebound

Bogies numbered

1, 2, 3, 9 and 10 also had varying degrees of curtailed rebound.

Bogie Number 1 only really came into use when either climbing

or 'nosing' . Bogie numbers 4 to 8 were allowed a full spring

deflection of 3 inches with a 2 inch rebound. Bogie number 11

was essentially a track tensioner rather than a strict suspension

unitand had a rebound of 2 inches and came into play every time

a gear change was made.

Fulcrum

Bosses

The bosses

into which the fulcrum shaft fitted were subject to some variation

amongst the Churchill series. On the early Churchills (MkI and

II) the bosses on all bogies were of the same pattern with the

fulcrum clamping nut below.

.

Later a strengthening

rib was added to the boss which also became longer....

...

and Bogies 1, 2, 9, 10 & 11 were modified to have shorter

bosses with the clamping nut moved to above the fulcrum shaft.

Bogie

Frame Rebound Lugs

Most

bogie frame lugs were of a 'two pronged' as shown below..

However,

bogies 1 & 2 were different pattern bogie incorporating an

extra central strengthening rib.

.

Bogie

11 was of yet another pattern being similar to 1 & 2 but without

the central rib.

Bogie

Frame Strengthening Strut

Bogies

1, 2, 9, 10 & 11 incorporate a strengthening strut which runs

across the bogie frame. On some vehicles bogie 8 also has the

additional strut (note this bogie has different pattern fulcrum

bosses than the others with similar struts). I've also come across

a strut on bogie 4 on one vehicle.

It

would appear that the orignal Churchill suspension units may not

have incorporated this strengthening strut as a report submitted

to the Tank Board by the Director of Armoured Fighting Vehicles

(A.C. Richardson) lists "Reinforced brackets Nos. 1, 2 and

11 bogies" as being and essential modification to ensure

battleworthyness of the Churchill in all theatres of war by spring

1942. The report recommennded that such reinforced brackets should

be included from tank No. 650.

Daily

Maintenance

As

one would expect, this suspension system required frequent maintenance.

The daily schedule (or every 50 miles if the daily mileage was

less than 50 miles) was to lubricate the bogie axles and fulcrum

shafts with gear oil (C.600) using a pressure gun and to inspect

and tighten the bolts on the on bogie bracket tie plates.

When

things get mixed!

Despite

the variations in details the bogie units were by and large interchangeable

if the situation required. The photo below shows a ARV MkII which

has some of the bogies positions mixed. Tthe combined 2 &

3 bogie unit fitted at stations 8 and 7. possibly this was to

strenghten the suspension under the winch gear but more likely

it is an accident of 'restoration" or maintenance.

So

what would you expect to see at the number 2 & 3 stations

?

From

the fulcrum boss we can see that bogie number 2 is not correct.

Bogies 2 and 3 have been welded together via the tie plate which

is actually the one that should fit between 10 and 11. Whether

the welding was to create a combined bogie or whether it was necesary

just because this plate does not have a bolt hole in the necessary

place - who knows!

|